Fleet operators face a significant challenge in today’s rapidly changing transportation and logistics sector which requires them to maintain a consistent supply of genuine vehicle parts.

The increasing focus on efficiency and sustainability improvement along with cost reduction has made it essential to address fleet parts supply as a major operation concern.

Traditional supply chains experience a transformation when artificial intelligence (AI) automation and data-driven decision-making systems are applied. Here we will detail the need for genuine parts, the significance of working with reliable suppliers and the impact of artificial intelligence in revolutionizing fleet parts supply.

The Importance of Genuine Parts in Fleet Operations

Fleet vehicles experience excessive usage which results in extensive mileage within short periods. The extended service life of each vehicle depends heavily on the quality of parts used in maintenance and repair activities since they experience thousands of miles per week. The role of genuine parts produced by original manufacturers stands as a crucial factor in the operation of fleets.

- Durability and Performance: Genuine parts deliver optimal performance and longevity as they meet the exact specifications of the vehicle.

- Warranty and Compliance: Genuine parts usually come with manufacturer warranties that provide security for fleet operators and maintain legal compliance with safety regulations.

- Vehicle Resale Value: The value of the vehicles in a well-maintained fleet that operates with genuine parts remains higher than those which use aftermarket components.

- Safety and Reliability: The risk of breakdowns and malfunctions decreases when using parts that meet strict quality control standards.

Challenges in Fleet Parts Supply

Even though genuine parts have clear advantages over other options fleet managers face multiple challenges during part component sourcing:

- Supply Chain Disruptions: Supply chains across the world experienced delays and shortages after the pandemic broke out.

- Counterfeit Products: The market is flooded with counterfeit parts which increase serious risks to vehicle safety and performance, making a reliable genuine parts supply essential.

- Cost Concerns: Higher prices of genuine parts lead some fleet managers to replace them with cheaper alternative parts that are often lower-quality alternatives.

- Inventory Management Issues: Maintaining the right balance of parts in stock without over-investing in inventory can be complex. Companies like STS-Global Scandinavian Parts Supply specialize in a reliable genuine parts supply providing, helping fleet managers overcome these challenges with ease

Finding Reliable Suppliers

A fleet parts supply chain operates effectively when it depends on multiple suppliers who offer reliable service. Fleet operators need to establish that their suppliers maintain trustworthy performance because they deliver consistent quality with capable supply capabilities.

- Right Partnerships: Established suppliers with direct partnerships with manufacturers guarantee genuine parts..

- Efficient Logistics:Suppliers with strong logistics networks ensure timely delivery of parts, and therefore lower the likelihood of downtime.

- Transparent Pricing: Fleet owners benefit from both competitive and open pricing structures which exclude hidden expenses and deliver financial clarity.

- Quality Assurance: A supplier’s commitment to quality control alongside industry certifications indicates the trust level.

- Customer Support: Timely customer service along with after-sales support creates a crucial difference in potential issues resolving.

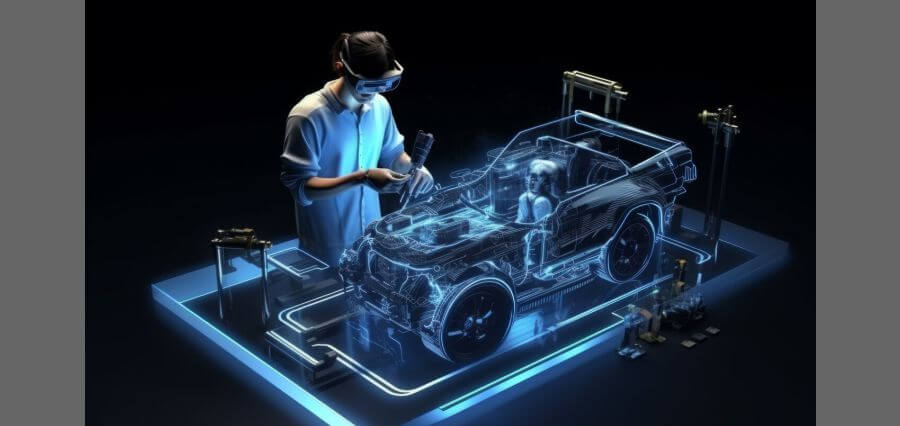

How AI is Transforming Fleet Parts Supply

The fleet parts supply industry experiences enhanced efficiency alongside predictive maintenance and supply chain management thanks to artificial intelligence (AI). Here’s how AI is making an impact:

Artificial Intelligence (AI) is significantly transforming the fleet parts supply industry by enhancing efficiency, predictive maintenance and supply chain management. Here’s how AI is making an impact:

- Predictive Maintenance and AI-Driven Diagnostics

Predictive maintenance systems powered by artificial intelligence utilize telematics information and IoT sensors to monitor vehicle operations in real-time. AI systems analyze previous data, that allows it to detect patterns and predict when particular vehicle components are likely to fail. This proactive approach helps fleet operators:

- Reduce unplanned downtime.

- Optimize maintenance schedules.

- Improve fleet safety and efficiency.

- Automated Inventory Management

Through AI-enabled inventory management systems fleet operators always have the right parts in stock and never go without needed components. These systems evaluate past maintenance records together with supplier delivery times and seasonal demand changes to determine inventory levels. Benefits include:

- Reduced excess inventory costs.

- Faster order fulfillment.

- Minimization of vehicle downtime.

- Supply Chain Optimization

By applying advanced algorithms AI enhances supply chain resilience through improved procurement approaches. Through advanced algorithms, AI can:

- Identify alternative suppliers in case of shortages.

- Optimize routing for faster deliveries.

- Predict demand fluctuations and adjust procurement accordingly.

- AI-Powered Supplier Selection

Choosing the right supplier is crucial for fleet operators, as their performance is critical for feets stability. AI-enabled analytics platforms evaluate a supplier’s performance based on delivery times and quality ratings along with pricing trends. AI allows fleet managers to:

- Identify the most reliable suppliers.

- Negotiate better contracts.

- Reduce procurement risks.

- Blockchain for Authenticity Verification

The use of counterfeit parts creates major safety and operational problems for any fleet vehicles. Blockchain technology with AI provides a secure part authenticity tracking system that cannot be altered. Fleet operators can verify the origin of parts through:

- Blockchain-enabled tracking systems.

- QR codes and RFID tags for authentication.

- AI-powered counterfeit detection mechanisms.

The Future of Fleet Parts Supply

The integration of AI into fleet parts supply chains is set only to grow. As technology continues to improve, so we can expect the following developments:

- Increased Adoption of Predictive Analytics: With the help of AI-powered predictive analytics, fleet management will see more accurate maintenance schedules because this technology will become standard practice.

- Automated Procurement Systems: Procurement systems powered by AI will select suppliers and negotiate prices while processing orders with minimal human interaction.

- Enhanced Supply Chain Resilience: Through the application of AI, fleet operators gain protection against risks by selecting multiple suppliers and diversifying supply chain disruptions.

- Greater Sustainability Initiatives: AI will help in the identification of environmentally friendly parts and optimizing logistics to reduce the carbon footprint of fleet operations.

Conclusion

The modern fleet parts supply sector is advancing through AI innovations alongside robotic process automation and data analytics. The reliability and safety of fleets depend on genuine parts, but sourcing them efficiently requires collaboration with trustworthy suppliers. Through AI technologies fleet operators are able to run inventory management with predictive maintenance and supply chain optimization. Fleet managers who embrace these technological advances will achieve lasting operational success together with financial savings and environmental sustainability.

In an era where efficiency and reliability are paramount, the application of AI in fleet parts supply is not merely beneficial, it is essential.

Source:https://www.insightssuccess.in/ai-and-emerging-tech-in-fleet-parts-supply-enhancing-reliability-and-efficiency/