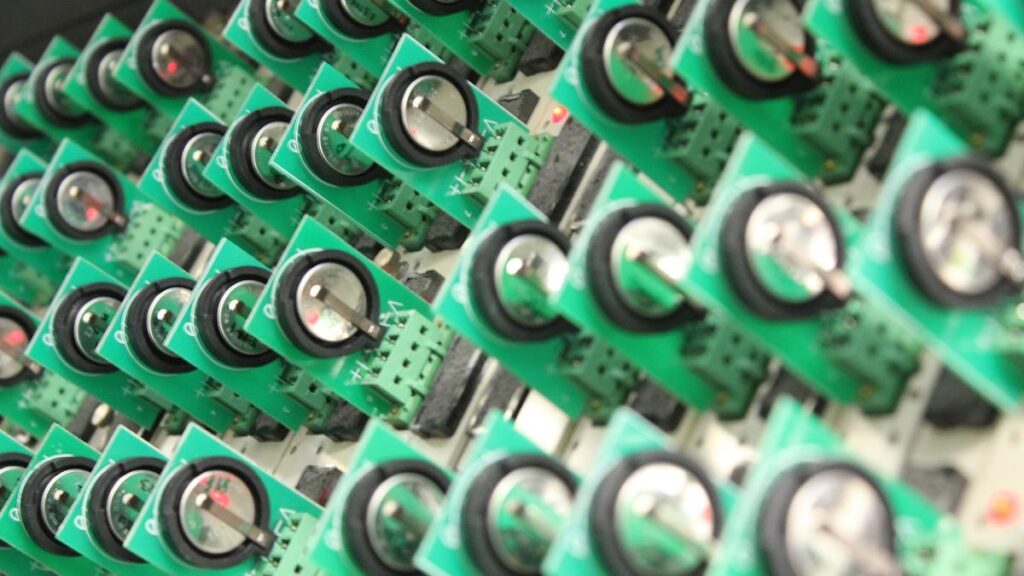

A batch of Li-ion coin cells being tested.

| Photo Credit: UCL Faculty of Mathematical and Physical Sciences

Scientists have reported in Science that the key to fixing solid-state battery (SSB) failures may lie in well-documented mechanical laws, paving the way for longer operational lifetimes.

A battery consists of an electrolyte sandwiched between the positive cathode and the negative anode. “In most batteries, including lithium-ion batteries in your cell phone, this electrolyte is a liquid solution, very similar to salt in water, that allows ions to move back and forth from the electrodes,” said Naga Phani B. Aetukuri, an associate professor at the Indian Institute of Science, Bengaluru, not involved in the new study. His team is among the top groups in India developing SSBs.

In a battery, ions move freely through the electrolyte while electrons flow from the cathode to the anode via an external circuit, charging the battery. In the reverse process, the electrons given up by the lithium (Li) anode travel to the cathode via the external circuit, powering it. Inside the battery, the corresponding lithium ions scurry to the cathode through the electrolyte during discharge.

‘Hairy roots’

In an SSB Li-ion battery, a ceramic block is the electrolyte. Solid electrolytes last longer, can store more energy, and are neither volatile nor flammable. Their solid structure separates the two electrodes well, reducing the need for bulky safety equipment and their weight. Currently, pacemakers and smartwatches use SSBs.

On the flip side, solids can crack, so solid electrolytes are inhospitable to volume changes or higher stress. This causes a persistent problem called dendrite growth. Li ions shuttle to the anode while charging and are deposited there, forming lithium filaments at the anode.

“Have you ever seen hairy roots growing from a central root? This occurs in plants to maximise their ability to receive nutrients,” Aetukuri said. Like a plant root, the anode tries to absorb as many ions as it can. “The dendritic growth of Li in SSBs maximises the anode’s ability to receive the most Li ions coming its way.” But like roots penetrate rocks, the dendrites pierce the electrolyte layer and reach the cathode, creating a short circuit.

Operando microscopy

Scientists don’t know the actual physical mechanism that causes such a failure. Now, researchers from Tongji University in Shanghai and other institutions have said the answer may lie in a known mechanical problem.

Metallic materials undergo fatigue due to cyclic loading and unloading. Cracks and fractures from fatigue account for over 80% of engineering failures. The researchers surmised that, as a metal, the Li anode in a battery could suffer similar damage from multiple charge-discharge cycles.

Dendrites “are microscopic features, meaning you need a microscope to visualise them. And you need to see while they are growing — that is when the cell is under operation,” Aetukuri said. For this, scientists use a technique called operando scanning electron microscopy: “a special microscopy technique where electrons are the light that lets you see what is happening at small dimensions.”

The researchers observed the anode-electrolyte interface under this microscope, monitoring its evolution as they charged and discharged the coin cell. The cell was initially stable, but after 30 minutes microscopic voids broke out, swelled, and snowballed into each other. The electrolyte finally snapped and the cell was short-circuited at the 145th cycle even though the amount of current was just a tenth of the maximum the cell could tolerate.

Bent back and forth

“Applying a small current in one direction may not lead to failure, but repeated cycles of charging and discharging can form structural defects, such as cracks, slip bands and voids,” a commentary published alongside the paper noted. As the battery underwent charge-discharge cycles, Li was stripped away from the anode before being plated back onto it, altering the amount of force exerted on the anode.

“You can cut a wire by using a cutter in a single go. … If you don’t have a cutter, you could bend the wire back and forth multiple times and the wire just breaks after a few times due to fatigue,” Aetukuri said. “This work shows that cycling the cell at low rates, equivalent to applying a low stress multiple times, can also lead to cell failure.”

“While not a lot might change in manufacturing, battery models that predict SSB failures will be a lot more sophisticated and likely more accurate due to this work,” Aetukuri said. The researchers wrote that future studies should investigate how Li’s stress-strain relationship varies with cycling rate and temperature.

Unnati Ashar is a freelance science journalist.

Published – May 18, 2025 06:00 am IST