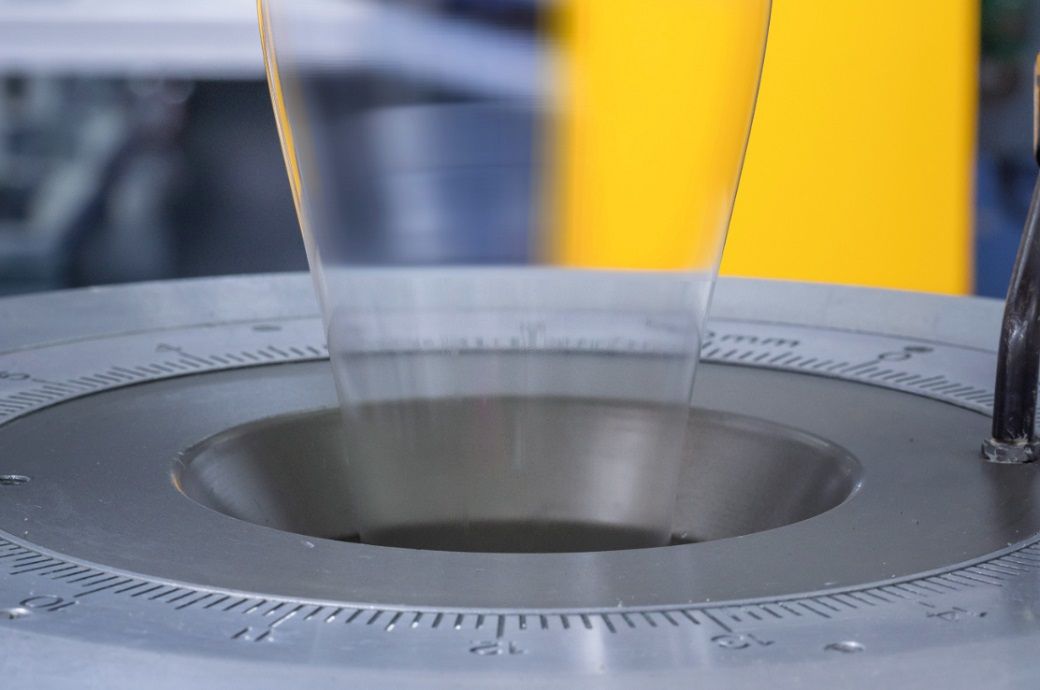

Getting ready for the K’ 2025 trade fair in Duesseldorf, Clariant announced the launch of its new AddWorks PPA product line, a new generation of PFAS-free polymer processing aids designed specifically for polyolefin extrusion applications. This innovative solution addresses the industry’s growing need for more sustainable alternatives to conventional fluoropolymer-based processing aids while maintaining strong performance standards.

Clariant has launched its PFAS-free AddWorks PPA line for polyolefin extrusion ahead of K’ 2025.

Designed for global markets, these aids enhance extrusion efficiency and surface quality while supporting recyclability and regulatory compliance.

The move aligns with Clariant’s sustainability goals and offers manufacturers a high-performance alternative to fluoropolymer-based aids.

The new range includes AddWorks PPA 101 FG, primarily focused on EMEA, Americas, and SEAP markets, and AddWorks PPA 122 G, targeted for Greater China and SEAP regions. Both products are readily commercially available, offering manufacturers a timely solution as regulatory restrictions on PFAS substances continue to tighten worldwide.

“Our new AddWorks PPA product line represents a significant breakthrough in sustainable polymer processing,” said Diederik Goyvaerts, Global Business Development Manager for Polymer Solutions at Clariant. “By developing PFAS-free alternatives that match or exceed the performance of traditional processing aids, we’re helping our customers stay ahead of regulatory changes while maintaining the high-quality standards their end-users expect.”

The innovative formulations are completely free of per- and polyfluoroalkyl substances (PFAS), as well as inorganic, silicone, or polysiloxane materials. This composition ensures broad regulatory compliance, including suitability for food contact and food packaging applications, addressing a critical need in the packaging industry. Additionally, these PFAS-free solutions support recyclability requirements under the upcoming EU Packaging and Packaging Waste Regulation (PPWR), further aligning with the industry’s sustainability objectives.

Manufacturers using the new AddWorks PPA solutions can expect significant processing improvements, including enhanced extrusion efficiency, effective elimination of shark skin defects, and superior film surface smoothness. The products also maintain neutral behaviour regarding optical and mechanical properties, with no negative impact on dyne level, sealability, or coefficient of friction – critical factors for downstream converting operations.

AddWorks PPA 101 FG features a 100% active fine grain composition that can be easily incorporated via host resin, masterbatch, or concentrate. Meanwhile, AddWorks PPA 122 G comes in a convenient masterbatch form for easy handling, requiring the same dosing level as traditional polymer processing aid masterbatches, simplifying the transition for manufacturers.

The versatility of these new processing aids makes them ideal for a wide range of applications, including polyethylene blown and cast film extrusion processes commonly used in packaging, agriculture, and building & construction industries. Film converters will particularly benefit from the improved surface quality and processing efficiency these additives provide.

Clariant’s introduction of the AddWorks PPA line reinforces the company’s commitment to developing more sustainable solutions that address both regulatory challenges and performance requirements. As global regulations increasingly target PFAS substances due to environmental and health concerns, Clariant’s proactive approach provides customers with future-proof solutions that maintain operational excellence while advancing sustainability goals. It underlines Clariant’s commitment to developing solutions that align with growing consumer and brand priorities for health, transparency, and sustainability. As demand rises for products that promote well-being and minimize environmental impact, Clariant provides innovative ingredients and materials that help brands meet evolving market expectations and regulatory requirements.

Note: The headline, insights, and image of this press release may have been refined by the Fibre2Fashion staff; the rest of the content remains unchanged.

Fibre2Fashion News Desk (HU)