Krunal Patel (left) and Amrit Om Nayak at Indra Water’s manufacturing unit in Bhiwandi

Image: Amit Verma

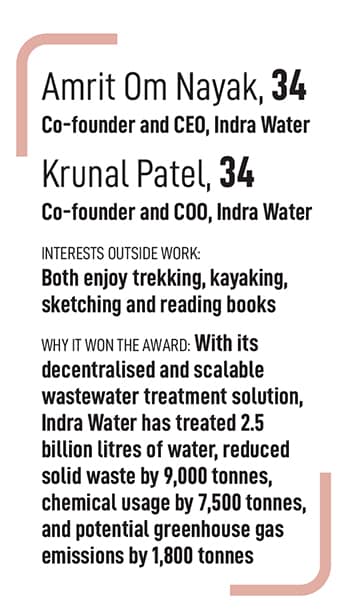

It all started in a small apartment in University Village, Seattle, in 2014, where a conversation between roommates sparked an idea. Though as students of mechanical engineering at the University of Washington both Krunal Patel and Amrit Om Nayak were working on different projects—Nayak on energy systems for spacecraft and Patel on underwater tidal turbines—what caught their attention was Seattle’s stormwater and its treatment.

“Seattle gets rain nine months of the year and though Seattle has wastewater treatment plants, we found that the stormwater mostly drains off and there was no cost-effective way to recover it,” says Nayak. Stormwater, he explains, is a distributed resource flowing in small streams and building a single centralised facility to clean that water is difficult and expensive.

It got them thinking about finding a decentralised solution, their goal being to create a modular, easily scalable technology for treating and recycling water. Early success got them thinking about a larger problem—wastewater from industrial and non-industrial establishments. “We soon shifted our attention to wastewater treatment, adapting our reactors to handle more complex pollutants,” adds Nayak.

As they built their first prototypes, they pondered their next move: Should they pursue their vision in the US or back home in India, where the need was greater? Reflecting on their roots and the potential impact, they decided to return to India where clean water remains scarce.

As they built their first prototypes, they pondered their next move: Should they pursue their vision in the US or back home in India, where the need was greater? Reflecting on their roots and the potential impact, they decided to return to India where clean water remains scarce.

“For instance, in southern India, many businesses and factories operate only three to four days a week due to severe water scarcity. This results in a loss of revenue,” says Nayak, who grew up in Chennai. “The lack of groundwater reserves exacerbates the issue, leaving them without a reliable backup source.” Despite being home to 18 percent of the world’s population, India has access to only 4 percent of the world’s water resources, and many areas have to deal with water scarcity.

The two returned to India in 2017 and set up Indra Water in 2018, tapping into the more recurring business opportunity offered in the treatment of waste water. India’s water and wastewater treatment market is the fifth largest globally, worth around $11 billion. It’s projected to reach $18 billion by 2026, according to the International Trade Administration (US Department of Commerce).

“The issue lies in how water is distributed and managed. We’re not capturing and storing rainwater, allowing it to percolate into aquifers. Instead, stormwater runoff goes to waste. Even the domestic sewage and industrial wastewater is not being treated properly, polluting freshwater bodies,” says Nayak, co-founder and CEO of Indra Water, at their factory in Bhiwandi, Maharashtra.

Though many industries have water treatment plants, they have often been left idle considering businesses could operate without having to worry about water availability, cost and compliances. However, with the cost of water going up due to scarcity, and stricter compliances, business continuity is threatened.

Indra Water’s decentralised technology leverages ionic reactions to remove pollutants—including a wide range of unwanted substances, heavy metals, suspended solids, phosphorus, fats, oil, grease, pathogens and dissolved organics, among others—from wastewater. Its proprietary water treatment solution is a plug-and-play solution, which takes 90 percent less space compared to existing solutions and recovers up to 99 percent of the treated water.

Existing mechanisms, designed for large, centralised structures, struggle to treat toxic water from individual buildings or districts. These traditional systems rely on homogenising water from various sources, allowing bacteria to break down pollutants over several days, explains Nayak.

Moreover, the conventional water treatment approaches, chemical and biological driven, require significant engineering, procurement, and construction infrastructure, which may take around eight to 12 months to get sanctioned. “In contrast, since Indra Water deploys solutions at the point of wastewater generation, the modular, space-efficient system saves energy and enables easy installation in buildings, recycling water within the same facility or building,” adds Patel, co-founder and COO of Indra Water. The solution treats highly polluted, fluctuating water quality in 40 seconds for sewage water and 240 seconds for pharmaceutical effluent, allowing for constant improvement in water quality and enabling water reuse, they say.

The solution is also scalable. The capacity depends on the size of the module. “We have different sizes, and the largest one can treat around a million litres per day of sewage,” says Nayak. However, the same module might treat 500,000 to 600,000 litres per day at a textile facility or 300,000 to 400,000 litres per day at a pharmaceutical unit. The idea is to multiply these modules based on the volume required, making it a scalable approach. Nayak adds that the solution, on an average, saves 35 percent in life cycle costs compared to conventional solutions. “The savings can be higher in industrial use cases,” he adds.

Also read: Forbes India Regional Goliath: How 100-year-old MTR keeps its legacy going

The Mumbai-based company focuses on treating wastewater from industries like textiles, steel, and pharmaceuticals, as well as sewage from hotels and commercial buildings. One of these is the Taj Mahal Palace Hotel in Mumbai, which has been using Indra Water’s solution to treat its wastewater. The hotel reuses 90 percent of its water, using it for everything from flushing and irrigation to car washing and laundry. The treated water is also used in the hotel’s boilers.

In the textile sector, Indra Water is working on treating wastewater from garment washing and printing. The company has partnered with Aditya Birla Group and is also working with Hindalco to deploy plants for treating wastewater from their aluminium processing units. Additionally, they are also working with Tata Electronics and electronics components maker Murata to address wastewater challenges in the electronics and semiconductor industries. Indra Water estimates that businesses can save up to ₹1-1.5 crore per year by adopting their solution.

Indra Water’s technology is also being used to treat difficult pollutant streams in the chemicals, pharmaceuticals, and agrochemicals sector. While the solution is capable of standalone treatment of wastewater, Indra is achieving greater optimisation by combining its technology with other solutions. It has combined its technology with solid separation hardware like Dissolved Air Flotation systems, biological systems, and chemical systems, membrane systems among others to provide cost-effective and comprehensive treatment of wastewater.

Indra Water’s technology is also being used to treat difficult pollutant streams in the chemicals, pharmaceuticals, and agrochemicals sector. While the solution is capable of standalone treatment of wastewater, Indra is achieving greater optimisation by combining its technology with other solutions. It has combined its technology with solid separation hardware like Dissolved Air Flotation systems, biological systems, and chemical systems, membrane systems among others to provide cost-effective and comprehensive treatment of wastewater.

The company is also exploring opportunities in water treatment for cooling towers. It has worked with data centre companies like CtrlS to establish the feasibility and efficacy of its solution for treatment and reuse of water with cooling towers.

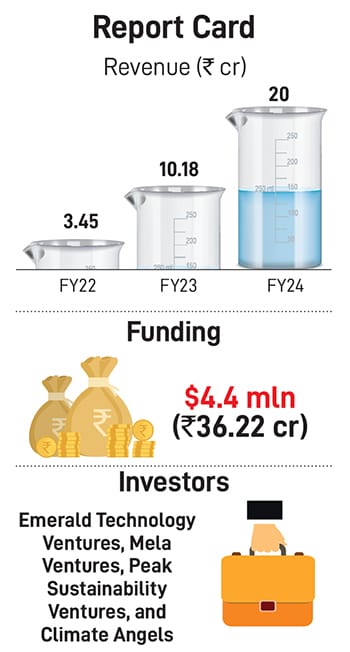

In January 2024, the cleantech startup raised $4 million in Series A funding, led by Emerald Technology Ventures, a Swiss fund with a focus on cleantech, and Mela Ventures. The round also saw participation from Peak Sustainability Ventures and The Climate Angels.

Since the investment, Indra Water has scaled up its treatment capacity from 575,000 litres per day to 3.75 million litres per day, achieving a 7x to 8x growth in eight months. It plans to add another 30 million litres of water per day treatment systems over the next 12 months. “Our current order pipeline exceeds ₹150 crore, with up to 50 million litres of water per day treatment systems lined up,” says Nayak.

To date, it has treated 2.5 billion litres of water, reduced solid waste by 9,000 tonnes, chemical usage by 7,500 tonnes, and potential greenhouse gas emissions by 1,800 tonnes. Already active in Southeast Asia, it plans to expand further into the Middle East region soon.

“Wastewater treatment at both sewage and effluent levels is often inadequate, either failing to meet compliance standards or being entirely neglected. With rising water costs, regulatory penalties, and potential shutdowns enforced by pollution control boards, organisations are prioritising efficient and effective wastewater treatment solutions,” says Suhani Doshi, VP Investments at Mela Ventures. “Indra’s solution is portable and deployment-ready. Its commercial viability—both in product design and business model—stood out as a key factor in our investment decision. They operate at the intersection of climate, water and industrial applications. Their approach to addressing industrial water challenges unlocks opportunities both in India and globally.”

According to Indra Water, India treats water without considering its reuse. Water treatment and reuse should be driven by the end-use application rather than a one-size-fits-all approach. For example, a paper and pulp facility can reuse water with a certain level of pollutants, but a hotel requires much cleaner water.

To address this, Indra Water advocates for a graded system that takes into account the pollutant load and the end-use application. This would create a fairer system, where companies are charged based on the actual services provided, rather than just the volume of water treated.

“We are actively engaging with the government to establish new standards that are relevant to India’s current needs. Agencies like the Bureau of Indian Standards should play a more active role in standardising frameworks for water treatment and reuse,” adds Nayak.

The recent Guillain-Barre syndrome outbreak in Pune highlights India’s urgent need for clean water and robust wastewater management, points out Anjal Prakash, clinical associate professor (research) at Indian School of Business. “Contaminated water is a major carrier of harmful pathogens like Campylobacter jejuni. Strengthening water treatment infrastructure, enforcing hygiene regulations, and investing in innovative sanitation solutions are crucial to preventing future health crises,” he says.

He adds that India faces issues like inadequate infrastructure, lack of stringent enforcement, high treatment costs, and low public awareness. “Many treatment plants operate below capacity due to poor maintenance, funding gaps, and technological inefficiencies, leading to untreated wastewater polluting water bodies and harming ecosystems,” says Prakash adding that public-private partnerships and policy-driven incentives can further accelerate sustainable wastewater management solutions across India.

Indra’s co-founders want to touch the lives of over 100 million people. “We are bringing the machine to the water. Thousands of our smart modular reactors will enable businesses and society to offset billions of litres of fresh water demand each day through treatment and reuse of wastewater, thereby mitigating water pollution and making fresh water available to the common man,” says Nayak.

Source:https://www.forbesindia.com/article/leadership/indra-water-creating-a-circular-economy-for-indias-wastewater/95556/1