Key Takeaways:

- Metal finishing encompasses a variety of processes aimed at altering the surface of metal products to enhance their appearance and performance.

- The primary techniques include electroplating, anodizing, and powder coating, each serving different functional and aesthetic purposes.

- Benefits include improved durability, aesthetic appeal, and corrosion resistance.

- Environmental challenges and recent innovations are shaping the future of the metal finishing industry.

Introduction

In both home and commercial uses, metal polishing is an essential step in the manufacturing process. Whether you aim to enhance a product’s visual appeal or improve its resistance to corrosion and wear, metal finishing processes provide the necessary touch. A metal finisher employs various techniques to achieve these goals, helping to extend the life and functionality of metal products.

In industries as diverse as automotive, aerospace, and electronics, metal finishing is not just an enhancement—it’s a necessity. Understanding the different processes and their benefits can aid manufacturers and hobbyists alike in choosing the right method for their applications. This guide aims to shed light on the intricacies of metal finishing, offering insights into how these processes contribute to product excellence.

Understanding Metal Finishing

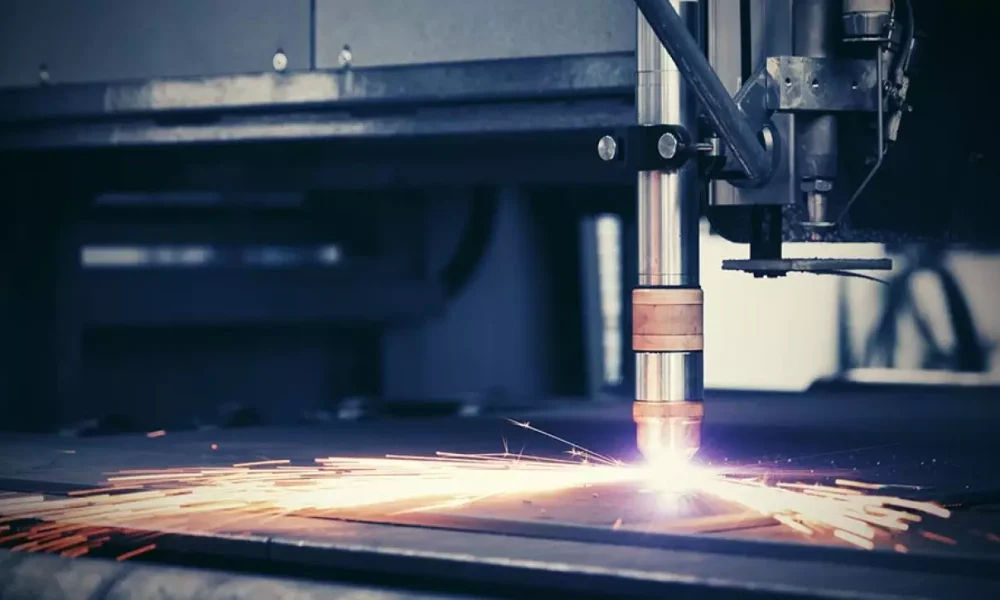

Metal finishing involves coating or modifying the surface of metal products to improve various characteristics. The process can involve mechanical, chemical, or electrochemical treatments that enhance a metal product’s durability, appearance, and resistance to environmental factors. Different industries utilize metal finishing to meet specific needs, from creating decorative finishes to ensuring that parts can withstand harsh usage.

Key Techniques in Metal Finishing

Electroplating

Electroplating is a popular method for coating a thin metal layer onto a substrate using an electric current. This technique serves multiple purposes: improving corrosion resistance, reducing friction, enhancing appearance, and increasing conductivity. It is often used in the automotive and electronics sectors to achieve precise coatings for performance and reliability.

Anodizing

Anodizing primarily serves aluminum products, enhancing natural oxidized layers into more durable and corrosion-resistant finishes. This process is valued for its protective qualities and for allowing aesthetic customization via vibrant color additions. Commonly seen in consumer electronics and architectural components, anodizing adds resilience and design flexibility.

Powder Coating

Powder coating is a dry finishing process known for its durability and environmental friendliness compared to liquid paint. Applying a powdered paint and then curing it under heat produces a thick, uniform finish that resists chipping and fading. Pair coating combines aesthetic appeal with versatile protection and is suitable for various applications, from household appliances to automobile parts.

Advantages of Metal Finishing

Metal finishing provides multiple advantages. It significantly enhances a product’s durability, helping to prevent wear and corrosion. This is particularly important in applications exposed to extreme environments, like industrial machinery or marine equipment. Moreover, metal finishing can radically improve a product’s aesthetic appeal, turning functional items into design pieces. An improved surface hardness further contributes to a metal item’s capability to withstand physical stresses without deforming or deteriorating.

Challenges and Solutions

While metal finishing offers substantial benefits, it also faces several challenges. The processes often involve hazardous chemicals, requiring careful disposal and adherence to environmental guidelines. The industry is moving towards greener solutions to address these issues, emphasizing recycling and waste reduction. Handling quality control across production batches and maintaining consistency also demand significant attention. Implementing advanced monitoring technologies and adhering to stringent quality standards can mitigate these challenges effectively.

Latest Innovations

Technology is making significant inroads in metal finishing, bringing new methods that enhance efficiency and sustainability. Research into nanostructured coatings is yielding robust surfaces with superior performance characteristics. Emphasis on sustainability inspires the creation of eco-friendly techniques that consume less energy and produce minimal waste. These advances promise to revolutionize the industry, offering compelling benefits for manufacturers keen on improving product quality while reducing their environmental footprint.

Implementing Best Practices

Following best practices is crucial to realizing the full potential of metal finishing. A foundational step is selecting the appropriate technique and materials for the intended application. Pre-treatment processes should be meticulously applied to ensure surfaces are fully prepared for finishing. Robust quality control strategies throughout production are vital for consistent results. Keeping abreast of new technologies and integrating innovations into the workflow will also provide a competitive edge, ensuring that products meet the highest standards of durability and appeal.

Summary

Metal finishing is a blend of artistry and precision engineering that equips metal products with essential enhancements in both form and function. The advantages of these procedures are becoming more widely available and significant as technology reshapes the sector. Understanding this field empowers manufacturers to optimize performance and highlights cutting-edge metal finishing practices’ broader environmental and economic advantages.