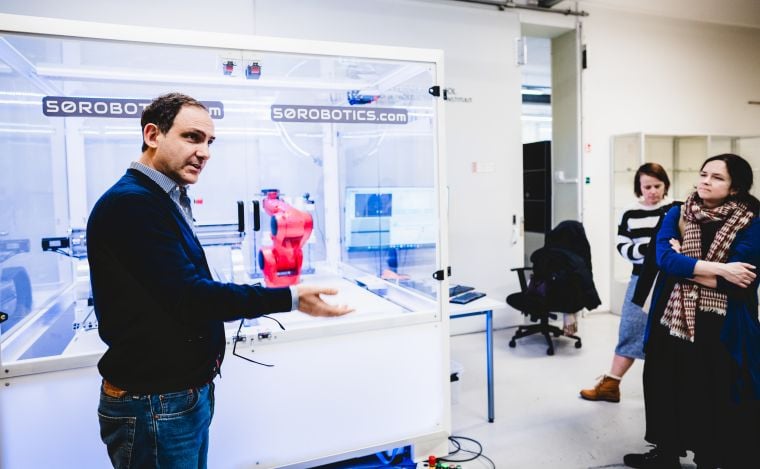

5.0 ROBOTICS CEO Carlo Lustrissimi during a lab visit

In a world where automation continues to reshape industries, 5.0 ROBOTICS aims to reimagine automation as an adaptive, collaborative system designed to augment human capabilities rather than replace them.

The Estonian deep tech startup develops advanced robotic automation systems integrated with artificial intelligence (AI). Built upon three key pillars—commercial CNC robots, dual-use defence robots, and the future-focused minifactory concept—the company is pushing boundaries in making manufacturing lighter, smarter, and more accessible.

In partnership with Singapore’s contract manufacturing veteran Giken Sakata, 5.0 ROBOTICS is bringing this vision to Southeast Asia (SEA). The collaboration, formalised in September 2024, focuses on embedding advanced manufacturing technologies within human-centred workflows.

During a visit to the company’s facility at Tallinn University of Technology, e27 observed the products that 5.0 ROBOTICS is building, including the mini factory. Compact, mobile, and versatile, the mini factory is designed to regionalise production, offering companies the ability to automate tasks without the need for sprawling factory floors.

Integrated with multi-axis robots, it allows for rapid reconfiguration based on production needs.

Also Read: Serving up the future: How robots are revolutionising the F&B industry

According to Carlo Lustrissimi, CEO of 5.0 ROBOTICS, the minifactory represents a shift in robotics from large-scale automation to human-centric design. “If we think about robotics, everybody imagines the big automotive assembly lines where humans have disappeared,” he explains.

“The fifth industrial revolution is bringing humans back. Robots should be functional to humans—to help people use their other values and not be stuck doing repetitive tasks.”

Lustrissimi adds that the future of robotics lies in cognitive capabilities, where machines can autonomously generate trajectories and adapt to production processes in real-time. “Today, traditional robotic technology requires pre-programmed trajectories. However, the future is for robots to think through the production process and react accordingly without human pre-configuration. The bottleneck is computing power, but AI is improving, and our estimate is that by 2025 or 2026, we will see affordable products capable of this level of autonomy.”

The minifactory is already positioned as a game-changer for Singapore’s manufacturing landscape, particularly for small and medium-sized enterprises (SMEs) seeking to adopt advanced automation without prohibitive costs. Lustrissimi emphasises that the next phase of the partnership is to roll out units within Giken Sakata’s ecosystem before expanding into foreign markets.

More ambitiously, the collaboration includes plans to establish a Robotics Academy in Singapore. The academy aims to upskill traditional manufacturing workers and train new talent in 5.0 ROBOTICS technologies.

“It is not just a knowledge partnership but also an operational one,” Lustrissimi shares. “We are also looking to open production of this technology in Singapore.”

Also Read: The transformation of chatbots: From rule-based robots to conversational companions

Founded in 1979, Giken Sakata’s expertise spans plastic injection moulding, precision machining, and complete assembly, supported by operations in Singapore, Indonesia, and China. The company’s partnership with 5.0 ROBOTICS reflects Singapore’s broader push to future-proof its manufacturing sector through the adoption of Industry 5.0 principles of combining technological innovation with human-centric design.

As global supply chains grow increasingly complex, Singapore is strategically investing in advanced manufacturing technologies to maintain competitiveness while creating high-value jobs. 5.0 ROBOTICS’s concept fits neatly into this narrative. Empowering workers rather than replacing them offers a sustainable model for countries like Singapore that are seeking to balance productivity with workforce wellbeing.

A national vision of AI

At a recent presentation attended by e27, Rannar Park, Head of Business Engagement at e-Estonia, highlighted Estonia’s ambitious AI strategy.

“Since 2023, we have over 100 AI use cases in government, built in collaboration with both private and public sectors,” he says.

From AI-driven traffic monitoring systems that optimise emergency response to personalised digital government services, Estonia is showcasing how AI can simplify daily life.

Park shared an example close to home: “In Estonia when a child is born, a digital Estonian is created automatically. Their electronic identity is set up, parental benefits are processed, and employers are notified—all with just a few clicks. It is a beautiful example of using AI to make lives easier.”

As more countries explore AI’s potential, this approach reminds us that the true value of this technology lies not in replacing human workers but in enhancing operations and easing the burdens of everyday tasks. By designing AI systems that support people through process streamlining, we can build a future where technology works alongside humans, empowering them rather than sidelining them.

—

Image Credit: Kristiina Tammik

The post With Giken Sakata partnership, 5.0 ROBOTICS is bringing human-centered robotics to Southeast Asia appeared first on e27.